Research

Chun-Wei Yao, Ph.D.

Associate Professor

Dr. Yao’s current research focus is in the areas of thin film characterization, surface engineering, nano-/microfabrication, nanoscale material properties, nanocomposite, microdroplets.

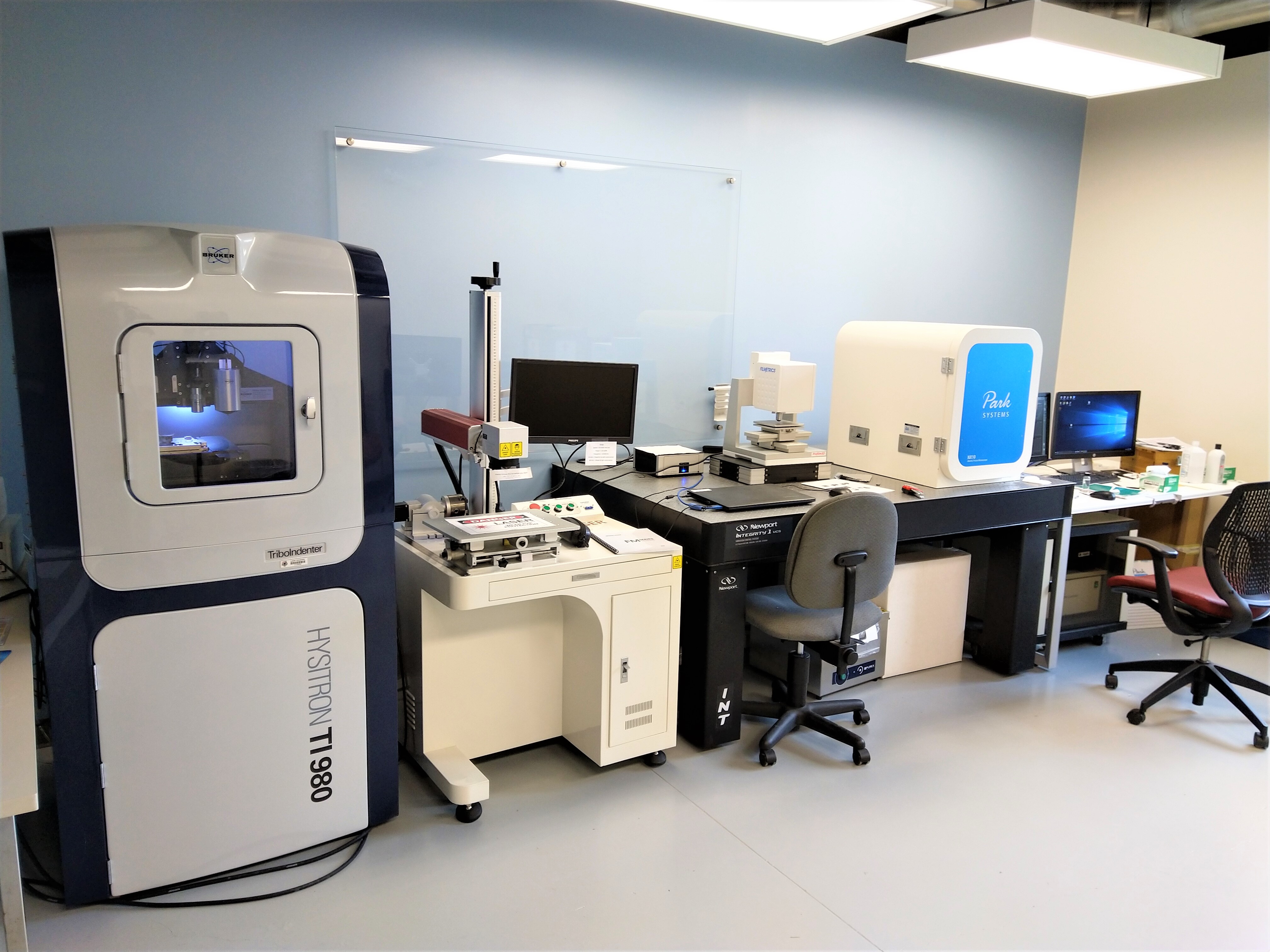

Advanced Materials and Surface Engineering Lab

The Advanced Materials and Surface Engineering Lab provides researchers in the Lamar University community with access to high-end instrumentation for the studies of material and surface properties. The lab is supervised by Dr. Chun-Wei Yao. The Advanced Materials and Surface Engineering Lab supports collaborative research projects with users from other Educational Institute and Industry. The lab also supports educational activities involving lab tours, workshops, hands-on demonstrations, outreach, and broader impact-related activities.

Projects

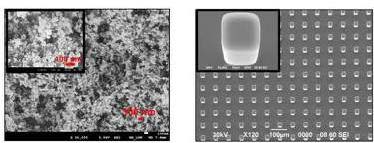

Bio-inspired Design

Hydrophobic surfaces which imitate the lotus architecture has a wide range of applications such as anti-icing and self-cleaning. The main objective is to fabricate and characterize nano/microstructured surfaces to study the underlying physical mechanisms responsible for enhanced hydrophobicity. The contact angle is the direct result of surface free energy minimization of the interfacial surfaces. Contact angle measurements were performed using a Goniometer for each engineered surface. Advancing, receding, and equilibrium contact angles were also measured. The technology could possibly be designed into an adhered coating for condensers to enhance dropwise condensation.

nanoparticle-based hydrophobic surface & structured hybrid surface

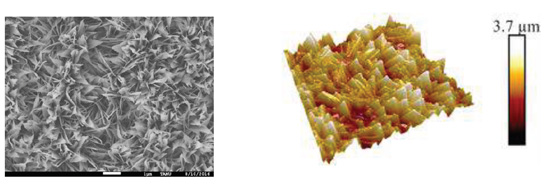

Anti-Corrosion & Anti-Fouling Coating

Corrosion and biofouling on metallic materials are serious problems. Up to now, various methods have been reported for developing anti-corrosion & anti-fouling coating on metallic surfaces. The majority of those methods has substantial limitations such as weak mechanical and wear stability. To face the challenges, Dr. Yao’s research team is working on different approaches to develop anti-corrosion & anti-fouling coatings. For example, Dr. Yao’s research team constructed nanostructured metallic surfaces (Fig. 2-4) by using chemical etching. Dr. Yao’s research team will continue to develop a simple, one or two step fabrication technique for anti-corrosion & antifouling coating.

(A) Scanning electron micrographs of a nanostructured copper surface, (B) Atomic force microscope image of a nanostructured copper surface, (C) Image of anti-corrosion and anti-fouling surface (2cm x 2cm)

Vibration on a Water Droplet

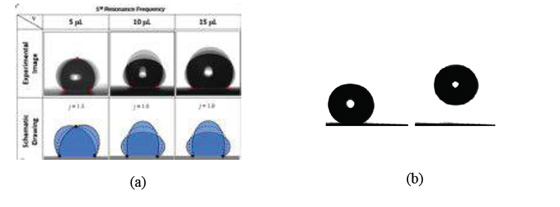

This vibration-induced droplet shedding method could find use in condensers, where rapid removal of condensate droplets and enhanced heat transfer performance is highly desirable. Droplet shedding processes were experimentally characterized using a high speed imaging system. The effects of vibration of droplet shedding were also studied. Vibrations were induced using a one-dimensional vibration generator coordinated by a square wave function generator to control the period and amplitude of vibration. Vibration modes were adjusted until sufficient resonance can be observed in an effort to understand its effects on droplet shedding.

(a)Experimental image and schematic drawing of the resonant frequencies for different droplet volumes, (b)Vibration-induced jumping motion of a 5 μl water droplet

Water Harvesting

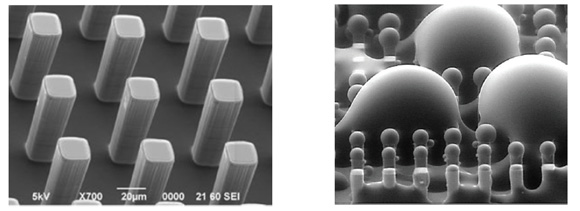

As climate change continues and long-term weather cycles change, access to fresh water for individual and agricultural use will be increasingly threatened around the world. Desert species offer valuable models for bio-inspired engineering of water-to-surface interactions at the nano and micro scale. This project will study the physics that governs water harvesting on engineering surfaces. Specifically, Dr. Yao’s research team will investigate how nano/micropatterning of the surface combine to create a surface effective at both condensing and collecting water at the macro-scale. Dr. Yao’s research team is developing and evaluating innovative engineering surfaces for water harvesting.

(A) SEM picture of the 50 μm spacing hybrid surface consisting of a micropillar array of hydrophobic and hydrophilic sites. The hybrid surfaces were fabricated through a photolithography process. The tops of the micropillars are hydrophilic. Bottom and side surfaces are hydrophobic. (B) Water droplets condense on the hybrid surface.