Research

Ping He, Ph.D.

Associate Professor

My research focus on developing multiscale, multi-physics numerical algorithms to address critical issues and grand challenges related to complex fluids in advanced technologies for chemical and/or biological applications. My ultimate goal is to accelerate the development of advanced technologies by clarifying their underlying physics. My research includes the modeling of

- Coupled thermodynamic and transport process of supercritical fluids mixtures

- Droplet-surface interactions; modeling of static and dynamic contact angles; hysteresis of contact angles; physics of contact line dynamics

- Study of bioprinting technologies using numerical models of multiphase flows and fluid-structure interactions

- Collaborations are always welcome!

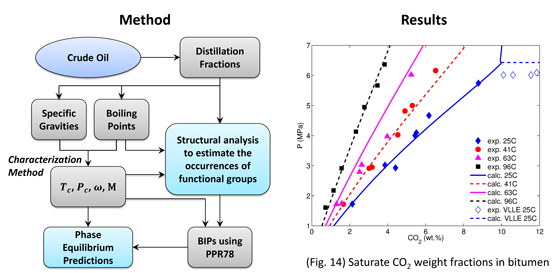

Phase Equilibrium Model for Mixtures of Crude Oil and Solvents Using Pseudocomponents for Crude Oil

Modeling flowchart on the left and phase equilibrium results of Athabasca bitumen and CO2 on the right. It is a generalized phase equilibrium model proposed by us for crude oil with/without solvents.

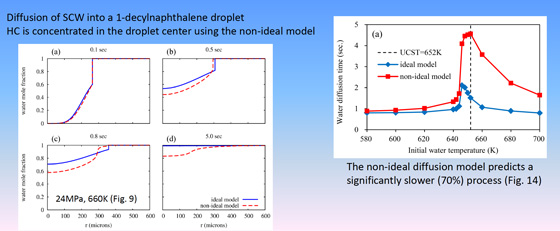

Mixing of Supercritical Water and Hydrocarbons

This work reveals the importance of the non-ideal diffusion driving force in the mixing of supercritical water and hydrocarbons.

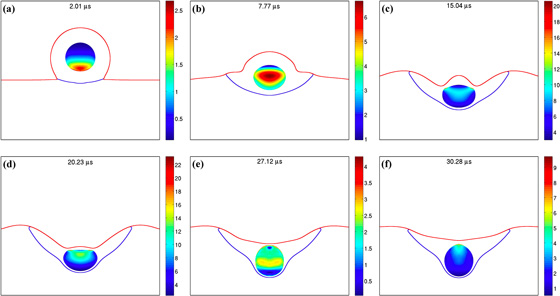

Impact of a Cell-Laden Droplet onto a Highly Viscous Bath

A cell printing process is simulated and shown above. The cell diameter is 30 μm, and droplet diameter 60 μm. The viscosity of the droplet is 1 cP, and that of the viscous bath is 20 cP. The shear modulus of cell is 10 kPa. The surface tension between liquid and air is 73 mN/m. The initial impact velocity is 4.5 m/s. The von Mises stress of cell is color-coded in the figure. The maximum stress occurs at 20.23 μs (frame d). Based on extensive numerical studies, four major stages of a cell printing process are identified.

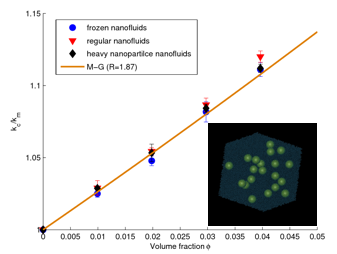

Heat Transfer in Nanofluids — Nanoparticle Suspensions

Our mesoscopic simulation tool based on the dissipative particle dynamics (DPD) captures the Brownian motions of nanoparticles suspended in the matrix fluids. Statistical calculations of the thermal conductivity of the nanofluids indicate that the heat transfer enhancement is ordinary and consistent with the average theory.

Polymer Screening in Electrokinetic Flows

Damping of the EOFs by polymer coating has been studied, and the scaling of these neutral polymers at different coating densities and flow velocities have been explored. This study revealed the effects of polymer alignment onto the friction of polymer layer in flow.