Large-scale Dynamic Simulation and Optimization for Industrial Flare Minimization during Plant Normal/Abnormal Operations

Qiang Xu, Ph.D.

Professor

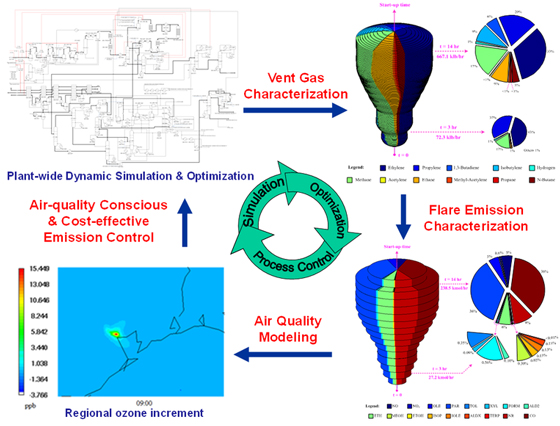

Flaring is crucial to the plant safety under normal/abnormal operations. However, excessive flaring, especially during chemical plant turnaround operations (start-up, shutdown, and upset), will burn large amounts of precious raw materials/off-spec products. Consequently, it will emit huge amount of volatile organic compounds (VOCs), highly reactive VOCs (HRVOC), CO, and NOx to the atmospheric environment; meanwhile result in tremendous industrial material and energy loss. Therefore, flare minimization is a triple-win thrust to benefits industries, regional communities, and environmental agencies.

Flare minimization through plant-wide dynamic simulation and optimization has been initiated and systematically studied and developed by our research group, which have also been demonstrated by multiple field tests. The general methodology framework starts with the establishment and fine-tuning of plant-wide steady-state and dynamic simulation models, which will be used to virtually run and examine the investigated normal/abnormal operating procedures for a studied plant. If a dangerous situation is identified, the operating procedures will be modified and checked again until the optimal operating procedures under realistic constraints are concluded. Various optimal designs with and without recycles together with different operating strategies have been modeled, studied, and summarized. According to our records, plant start-up/shutdown flares can be generally reduced by over 50% with the help of our plant-wide dynamic simulations.

Selected References

- Xu, Y. L., Yu L., Wang, S. J. Xu, Q.*, Ho, T.C., “New Flare Minimization Strategies with Consideration of Multi-Plant Material Exchange”, Journal of Cleaner Production, 282, 124508, 2021. (2021 Best Paper Award of AIChE Process Development Division)

- Xu, Y. L., Wang, S. J., Xu, Q.*, “An Integrated Flare Minimization Methodology for Simultaneous Turnaround Operations of Two Chemical Plants”, Journal of Cleaner Production, 277, 123181, 2020.

- Xu, Y. L., Dinh H., Xu, Q.*, Eljack F., El-Halwagi, M., “Flare Minimization for An Olefin Plant Shutdown via Plant-wide Dynamic Simulation”, Journal of Cleaner Production, 254, 120129, 2020. (2020 Best Paper Award of AIChE Environmental Division).

- Mazumder, M., Chen, L.W., Xu, Q.*, “Integration of Ejector-based Flare Gas Recovery and Desalination Processes for Produced Water Onsite Treatment in Shale Gas Production”, Chemical Engineering & Technology, 43(2), 200–210, 2020.

- Fernandes, D., Wang S., Xu Q., Chen D.*, “Dynamic Simulations of the Allam Cycle Power Plant Integrated with an Air Separation Unit”, International Journal of Chemical Engineering, 1-10, 2019.

- Emdadul, H., Xu, Q.*, Palanki, S., “Glycol Loss Minimization for A Natural Gas Dehydration Plant under Upset Conditions”, Industrial & Engineering Chemistry Research, 58, 1994-2008, 2019.

- Xu, C. X, Xu, Q.*, “A Novel Design for Simultaneous Production of Biodiesel and Glycerol Carbonate from Soybean Oil”, Industrial & Engineering Chemistry Research, 57(49), 16809–16816, 2018.

- Shama, M. A. A., Xu, Q.*, “Optimal Design of Gas-Expanded Liquid Ethylene Oxide Production with Zero Carbon Dioxide Byproduct”, Industrial & Engineering Chemistry Research, 57(15), 5351-5358, 2018.

- Kurle, Y. M., Xu, Q.*, Palanki, S., “Dynamic Simulation Study for Boil-off Gas Minimization at Liquefied Natural Gas Exporting Terminals”, Industrial & Engineering Chemistry Research, 57 (17), 5903–5913, 2018.

- Wang, S., Zhang J., Wang, S. J., Xu, Q.*, “Dynamic Simulation for Flare Minimization in Chemical Process Industry under Abnormal Operations”, Current Opinion in Chemical Engineering, 14, 26-34, 2016.

- Dinh H., Eljack F., Wang, S. J., Xu, Q.*, “Dynamic Simulation and Optimization Targeting Emission Source Reduction during An Ethylene Plant Start-up Operations”, Journal of Cleaner Production, 135, 771-783, 2016.

- Dinh H., Zhang, S. J., Xu, Y. L., Xu, Q.*, Eljack F., El-Halwagi M. “A Generic Approach of Using Dynamic Simulation for Emission Reduction under Abnormal Operations: Scenario Study of An Ethylene Plant Startup”, Industrial & Engineering Chemistry Research, 53 (39), 15089-15100, 2014.

- Wang, Z. Y., Xu, Q.*, Ho, T. C., “Emission Source Characterization during An Ethylene Plant Shutdown”, Chemical Engineering & Technology, 37, 1-12, 2014.

- Zhao, Y.C., Zhang, J., Qiu, T., Zhao, J.S., Xu, Q.*, “Flare Minimization during Start-ups of An Integrated Cryogenic Separation System via Dynamic Simulation”, Industrial & Engineering Chemistry Research, 53 (4), 1553-1562, 2014.

- Wei, T., Hou, X. F., Yu, J. T., Zhang, J., Xu, Q.*, Zhao, J. S., Qiu, T., “Shutdown Strategy for Flare Minimization at An Olefin Plant”, Chemical Engineering & Technology, 37(4), 1-7, 2014.

- Fu, J., Xu, Q.*, “Simultaneous Study on Energy Consumption and Emission Generation for An Ethylene Plant under Different Start-up Strategies”, Computers & Chemical Engineering, 56, 68-79, 2013.

- Yang, X. T., Xu, Q.*, Li K. Y. “Safety-Considered Proactive Flare Minimization during Ethylene Plant Upsets”, Chemical Engineering & Technology, 34(6), 893-904, 2011.

- Yang, X. T., Xu, Q.*, Li, K. Y., Sagar, C. D., “Dynamic Simulation and Optimization for the Startup Operation of An Ethylene Oxide Plant”, Industrial & Engineering Chemistry Research, 49 (9), 4360-4371, 2010. (2010 Best paper award of AIChE Process Development Division)

- Liu, C. W., Xu, Q.*, “Emission Source Characterization for Proactive Flare Minimization during Ethylene Plant Start-ups”, Industrial & Engineering Chemistry Research, 49(12), 5734-5741, 2010. (2010 Best paper award of AIChE Sustainability Forum)

- Yang, X. T., Xu, Q.*, Li, K. Y. “Flare Minimization Strategy for Ethylene Plants”, Chemical Engineering & Technology, 33(7), 1-8, 2010.

- Xu, Q.*, Yang, X. T., Liu, C. W., Li, K. Y., Lou, H. H., Gossage, J. L., “Chemical Plant Flare Minimization via Plant-Wide Dynamic Simulation”, Industrial & Engineering Chemistry Research, 48(7), 3505-3512, 2009.

- Yang, X. T., Xu, Q.*, Zhao, C., Li, K. Y., Lou, H. H., “Pressure-driven Dynamic Simulation for Improving the Performance of A Multi-stage Compression System during Plant Startup”, Industrial & Engineering Chemistry Research, 48(20), 9195-9203, 2009.

- Xu, Q.*, Li, K. Y., Yang, X. T., Liu, C. W., Romero, R. O., Mekala, U. R., Lou, H. H., Gossage, J. L., “Flare Minimization for Chemical Plant Turnaround Operation via Plant-wide Dynamic Simulation,” Proceedings of FOCAPO 2008, 247-250, M. Lerapetritou, M. Bassett, S. Pistikopoulos, CACHE Corporation, Boston, MA, USA.

- Li, K., Xu, Q., Lou, H. H., Gossage, J. L., Singh, A., Vragolic, S., and Kelly, T., "Flare Minimization during Plant Startup via Dynamic Simulation", Proceedings of PSE ASIA 2007, Xi’an, China, 2007.