Energy Saving and BOG Minimization for LNG Industry

Qiang Xu, Ph.D.

Professor

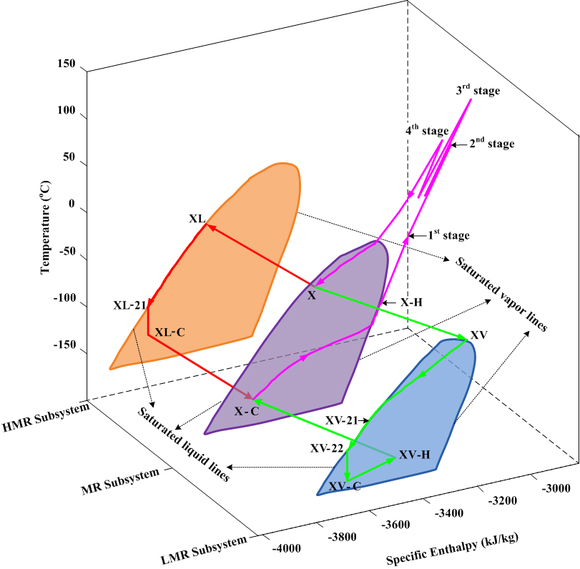

LNG liquefaction process and LNG re-gasification process are most two important sectors of the entire LNG value chain. Tremendous energy and material saving opportunities are existing in these two process sectors. Meanwhile, boil-off gas (BOG) generation and handling problems in these processes become increasingly important due to more intensive global competitions and stricter environmental regulations. In this research area, thermodynamic-analysis-based simulation and optimization studies on energy consumption minimization and BOG minimization have been comprehensively performed. Meanwhile, various factors causing BOG generations are quantitatively studied together with different strategies to minimize, recover, and reuse produced BOG, targeting the best performance of energy saving and processing efficiency.

Associated with the above research area, we have also studied how to recover natural gas liquids in energy efficient ways. Both shale gas and LNG contain certain amounts of C2+ hydrocarbons (NGL), which might profitably be recovered. To accomplish this, the shale gas stream needs cold energy to chill down and scrub NGL; while the LNG stream needs hot energy to evaporate and separate from NGL. Thus, integrating both processes of shale gas processing and LNG re-gasification, so as to utilize cold energy from LNG re-gasification process to assist the NGL recovery, has potentially significant benefits on both energy savings and high-value product productions. Based on our study, a new methodology to guide the conceptual design and operation for such a process synthesis has been developed, where the uncertainty of shale gas feed rate changes has been considered. The methodology includes four steps of work: superstructure development and data preparation, synthesis model development and solution identification, heat exchanger network design, and final process validation via rigorous simulations. Compared with available studies, there are two major contributions: (1) a new optimization model is developed; and (2) process synthesis with consideration of the uncertainty of shale gas feed rate, which enhanced future operational flexibility of the conceptual design.

Selected References

- Mahmud, M. A., Khan, R. I., Wang, S. J., Xu, Q.*, “Comprehensive Study on Sloshing Impacts for An Offshore 3D Vessel via the Integration of CFD Simulation, Experimental Unit, and ANN Prediction”, Industrial & Engineering Chemistry Research, 59(51), 22187-22204, 2020.

- Mazumder, M., Xu, Q.*, “Modeling and Optimization for A Comprehensive Gas Processing Plant with Sensitivity Analysis and Economic Evaluation”, Chemical Engineering & Technology, 2198-2207, 2020

- Wang, X. C., Xu, Y. L., Wang, S. J., Ho, T. C., Xu, Q.*, “Comprehensive Study on Boil-off Gas Generation from LNG Road Tankers under Simultaneous Impacts of Heat Leakage and Transportation Vibration”, Fuel, 275, 117876, 2020.

- Emdadul, H., Xu, Q., Pakanki, S.*, “Advanced Process Control for Cost-effective Glycol Loss Minimization in A Natural Gas Dehydration Plant under Upset Conditions”, Industrial & Engineering Chemistry Research, 59(16), 7680–7692, 2020.

- Emdadul, H., Xu, Q.*, Palanki, S.*, “Glycol Loss Minimization for A Natural Gas Dehydration Plant under Upset Conditions”, Industrial & Engineering Chemistry Research, 58, 1994-2008, 2019.

- Mazumder, M., Xu, Q.*, “Study for the Optimal Operation of Natural Gas Liquid Recovery and Natural Gas Production”, Natural Gas Processing from Midstream to Downstream, Editors: Nimir O. Elbashir, Mahmoud M. El-Halwag, Kenneth R. Hall, Ioannis Economou, Wiley, ISBN: 978-1-119-27025-6, January 2019.

- Mahmud, M. A., Mazumder, M., Xu, Q.*, Khan, R. I., “Sloshing Impact on Gas Pre-treatment for LNG Plants Located in Stranded Offshore Location”, Industrial & Engineering Chemistry Research, 57(17), 5764–5775, 2018.

- Kurle, Y. M., Xu, Q.*, Palanki, S., “Dynamic Simulation Study for Boil-off Gas Minimization at Liquefied Natural Gas Exporting Terminals”, Industrial & Engineering Chemistry Research, 57 (17), 5903–5913, 2018.

- Kurle Y. M., Wang, S. J.*, Xu, Q.*, "Dynamic Simulation of LNG loading, BOG Generation, and BOG Recovery at LNG Exporting Terminals", Computers & Chemical Engineering, 97, 47-58, 2017.

- Kurle Y. M., Wang, S. J.*, Xu, Q.*, "Simulation Study on Boil-off Gas Minimization and Recovery Strategies at LNG Exporting Terminals", Applied Energy, 156, 628-641, 2015.

- Wang, M. Q., Xu, Q.*, “Optimal Design and Operation for Simultaneous Shale Gas NGL Recovery and LNG Re-gasification under Uncertainties”, Chemical Engineering Science, 112, 130-142, 2014.

- Wang, M. Q., Zhang, J., Xu, Q.*, “A Novel Conceptual Design by Integrating NGL Recovery and LNG Re-gasification Processes for Maximum Energy Savings”, AIChE Journal, 59(12), 4673–4685, 2013.

- Wang, M. Q., Zhang, J., Xu, Q.*, “Optimal Design and Operation of C3MR Refrigeration System for Natural Gas Liquefaction”, Computers & Chemical Engineering, 39, 84-95, 2012.

- Wang, M. Q., Zhang, J., Xu, Q.*, Li, K. Y. “Thermodynamic-Analysis-Based Energy Consumption Minimization for Natural Gas Liquefaction”, Industrial & Engineering Chemistry Research, 50 (22), 12630–12640, 2011. (2012 Best paper award of AIChE Process Development Division)

- Liu, C. W., Zhang, J., Xu, Q.*, Gossage, J. L., “Thermodynamic Analysis-based Design and Operation for Boil-off Gas Flare Minimization at LNG Receiving Terminals”, Industrial & Engineering Chemistry Research, 49(16), 7412-7420, 2010. (2010 Best paper award of AIChE Environmental Division)