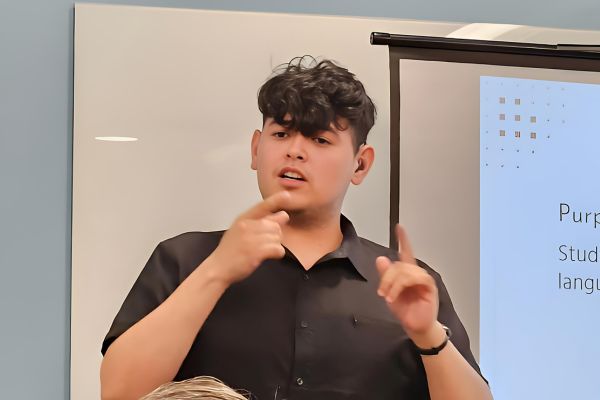

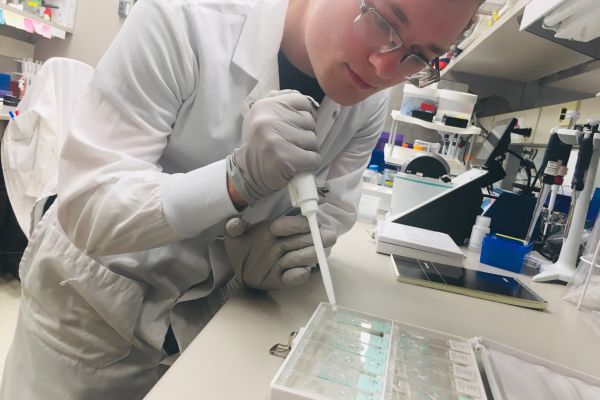

Research

At Lamar University our research efforts make a hands-on difference in the lives of the people we serve. From NASA experiments to cutting-edge research in engineering, nursing, business, the arts, sciences and more, Lamar students and faculty are changing the way we see the world around us.

Research Centers

Research News

April 25, 2024

LU’s Dr. Julie Fischer has unveiled groundbreaking insights into the role of imperial patronage and the empowerment of women in Ancient Rome through the publication of her latest book, "Power and Propaganda: Large Imperial Cameos of the Early Roman Empire."

Read More

Tue, April 02, 2024

Fri, March 01, 2024

Fri, February 16, 2024

Tue, November 28, 2023